atomatik ball dauke ABB mota gilashin edging polishing inji

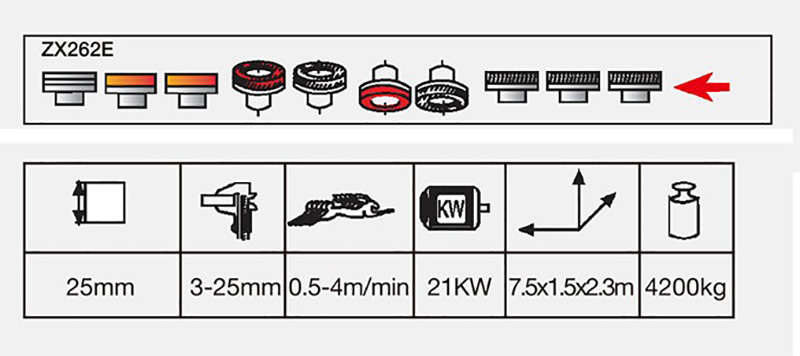

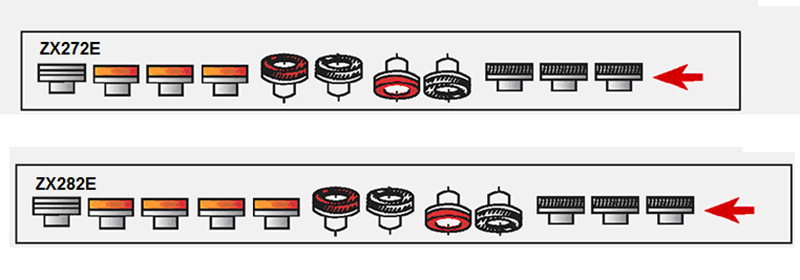

ZX262E / ZX272E / ZX282E

Mitsubishi PLC sarrafawa da taɓa tsarin aiki na panel

high daidaici ball hali tsarin ball barga motsi & kyau hana ruwa yi

Mai ɗaukar kaya na baya yana da goge goge, wanda, ya kiyaye tsabtace ƙasa kuma ya ba da tabbacin sakamakon aiki

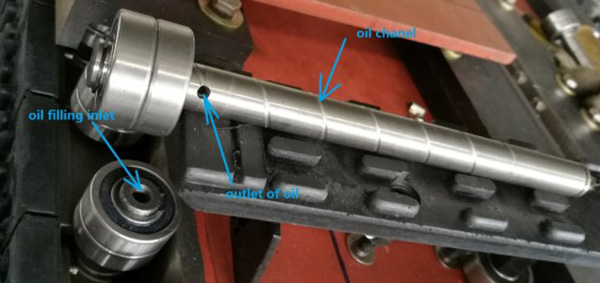

tsarin lubrication

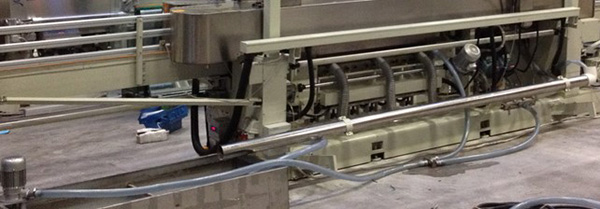

Bakin karfe zagayawa tsarin

Gabatarwar Injin

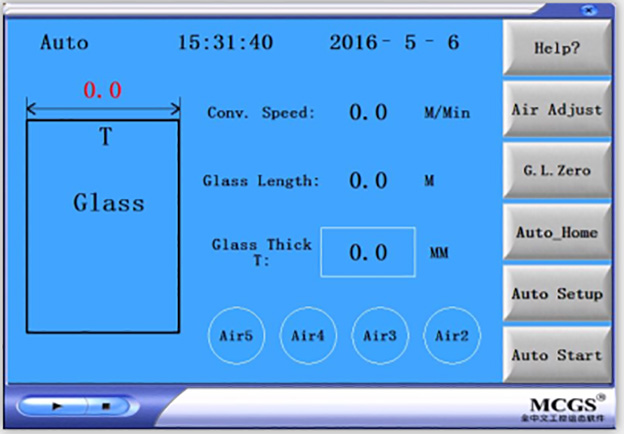

a) Tsarin sarrafawa:

Wannan injin yana amfani da sarrafa PLC da tsarin sarrafa kwamiti mai tabawa. Injin na iya aiki a cikin yanayin atomatik da kuma yanayin jagora.

b) Mai Gudanarwa:

Mai ɗaukar hoto ya ɗauka tsarin watsawa ba tare da sarkar ba, wanda ya kunshi bearings uku mirgina tare da madaidaicin zafin jagorar karfe, motsin gilashi yana da karko sosai.

Abubuwan da ake amfani dasu na mai jigilar kaya na gaba da na baya ana shafa mai ta atomatik ta hanyar famfon mai, hanyar da aka tsara ta mai da kyau ta ba da damar sama da kasa don samun mai daidai.

Mai jigilar baya yana da goge gogewa, wanda, ya kiyaye tsabtace wuri kuma ya ba da tabbacin sakamakon aiki.

c) Injin yana da injin kare kaurin gilashi. Lokacin da aka saka gilashin kauri mara kyau a cikin inji. Injin zai tsaya kai tsaye. Wannan yana kare bearings daga murkushewa.

d) Loading / off loading conveyor amfani da lokaci bel. Yana iya daidaita tsawo don saita cire gilashin daban.

e) Gilashin talla na gilashi suna amfani da sandar extrusion na Aluminum, tare da abin nadi mai tallafi.

f) An yi murfin mai ɗaukar kaya a cikin baƙin ƙarfe.

g) Motsi mai jigilar kaya yana da motsi. Ana iya daidaita shi ta maɓallin lantarki akan allon aiki ko daidaitacce ta atomatik. An nuna kaurin a allo. Hakanan akwai karatun inji don nuna kaurin gilashi.

h) Daidaita saurin aiki:

Aiki gudu ne daidaitacce ta hanyar m inverter.

i) Spindles ana kera su da kyawawan injina ABB.

j) Tsarin ruwa

Ana zagaya ruwa a cikin mashin din da kuma bakin ruwa na bakin karfe. An sanya bututun ƙarfe mai bakin karfe a bayan mashin don malale ruwa daga tankin ƙafafun. Ana tsabtace ruwa mai tsabta zuwa inji ta bututun ruwa murabba'i. Shigarwa da tsarin zagayawar ruwa yana da sauqi.

Sigogin fasaha

| Abu | Sigogi | Yankin |

| 1 | Spindles: | 9 shugabannin. |

| 2 | aiki Speed: | 0.1m-3.8m / min |

| 3 | Nika zurfin: | 3mm |

| 4 | Max. fadin Arris: | 2.5mm |

| 5 | Girman gilashi: | 3mm-30mm |

| 6 | Min. Girman gilashi: | 25mmX25mmX8mm |

| 7 | Powerarfin :arfi: | 19.85kw |

| 8 | Gabaɗaya Girma: | 8.0mx1.2mx2.0m |

| 9 | Jimlar nauyi: | 5700kg |