Gilashi ɗayan shahararrun kayan aiki ne da ake amfani dasu a yau, saboda wani ɓangare na inganta ingantaccen hasken rana da yanayin zafi. Wata hanyar da wannan nasarar ta samu shine ta hanyar amfani da wucewa da sarrafa hasken rana ƙananan-e coatings. Don haka, menene gilashin ƙaramin e? A cikin wannan ɓangaren, muna ba ku cikakken zurfin bayyani game da sutura.

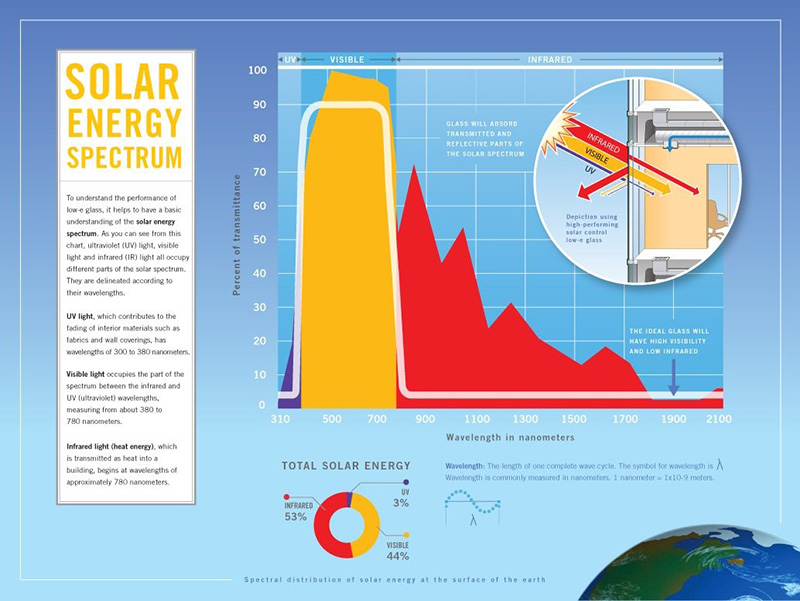

Domin fahimtar kwalliya, yana da mahimmanci fahimtar hasken makamashin hasken rana ko makamashi daga rana. Hasken Ultraviolet (UV), haske mai bayyana da hasken infrared (IR) duk sun mamaye sassa daban-daban na hasken rana - bambance-bambancen da ke tsakanin ukun an yanke su ne ta hanyar tsayin su.

• Hasken Ultraviolet, wanda shine yake haifar da kayan ciki kamar yadudduka da murfin bango su dusashe, yana da nisan mita 310-380 a lokacin da yake ba da rahoton aikin gilashi.

• Bayyanannen haske yana ɗauke da ɓangaren bakan tsakanin ƙarfin zafin daga kusan 380-780 nanometers.

• Ana watsa hasken infrared (ko makamashin zafin rana) azaman zafi a cikin gini, kuma yana farawa daga zafin nina 780. Ana kiran infrared na hasken rana azaman makamashin infrared mai gajeren zango, yayin da zafin da yake fitowa daga abubuwa masu dumi yana da tsayi fiye da rana kuma ana magana dashi azaman infrared mai tsawa.

An haɓaka ƙananan sutura don rage adadin ultraviolet da hasken infrared wanda zai iya wucewa ta cikin gilashi ba tare da lalata ƙarfin hasken da ake gani ba wanda ake watsawa.

Lokacin da haske ko makamashi mai haske ya sha gilashi, ko dai ya juya ta hanyar iska mai motsi ko sake haskakawa ta saman gilashin. Abilityarfin abu don haskaka makamashi sananne ne da emissivity. Gabaɗaya, kayan da ke nuna ƙyalli suna da ƙarancin emissivity kuma abubuwa masu duhu masu duhu suna da babban emissivity. Duk kayan aiki, gami da tagogi, suna haskaka zafi a cikin sigar dogon-lokaci, makamashin infrared dangane da emissivity da yanayin zafin saman su. Haske mai haske yana ɗayan mahimman hanyoyin canja wurin zafin rana tare da windows. Rage ƙarancin haske na ɗaya ko fiye na saman gilashin taga yana inganta kaddarorin hana rufin taga. Misali, gilashin da ba a lullube shi yana da tasiri na .84, yayin da Vitro Architectural Glass '(tsohon gilashin PPG) mai sarrafa hasken rana Solarban® Gilashin 70XL na da emissivity na .02.

Wannan shine wurin da sutura masu ƙarancin emissivity (ko ƙaramin e-e) suka fara wasa. Gilashin Low-E yana da siraran microscopically, bayyanannen rufi - ya fi siririn siriri fiye da na ɗan adam-wanda ke nuna ƙarfin infrared mai tsawon-zafi (ko zafi). Wasu ƙananan-e's suna nuna mahimmancin ƙarfi na ƙarfin infrared hasken rana. Lokacin da makamashin zafin ciki ya yi ƙoƙarin tserewa zuwa sanyi a waje a lokacin hunturu, ƙaramin e-e yana nuna zafi a cikin ciki, yana rage hasara mai zafi ta cikin gilashin. Baya baya faruwa yayin bazara. Don amfani da kwatancen mai sauƙi, ƙaramin e-e yana aiki iri ɗaya kamar thermos. Thermos yana da rufin azurfa, wanda ke nuna yawan zafin abin sha da yake ciki. Ana kiyaye yawan zafin jiki saboda yawan tunani da ke faruwa, da kuma fa'idodi na inshora waɗanda sararin samaniya ke bayarwa tsakanin bawon ciki da na baya na thermos, kwatankwacin naúrar gilashin da ke rufewa. Tunda gilashin low-e yana dauke da siraran siraran bakin siraransu ko wasu ƙananan kayan emissivity, ka'ida ɗaya take aiki. Shafin ƙaramin e-azurfa yana nuna yanayin ƙarancin ciki a ciki, yana kiyaye ɗumi dumi ko sanyi.

Nau'in Coananan Nau'in Shafi & Tsarin Masana'antu

A zahiri akwai nau'ikan launuka daban-daban daban-daban guda biyu: launuka masu ƙarancin e-pass da ƙarancin hasken rana masu ƙarancin ƙarfi. An tsara suttura masu ƙarancin ƙarfi don haɓaka haɓakar zafin rana a cikin gida ko gini don ƙirƙirar tasirin dumama "wucewa" da rage dogaro da ƙarancin wucin gadi. Designedarfin wutar lantarki mai ƙananan-e an tsara shi don iyakance adadin zafin rana wanda ya wuce cikin gida ko gini da nufin kiyaye gine-ginen sanyaya da kuma rage yawan kuzarin da ke da alaƙa da kwandishan.

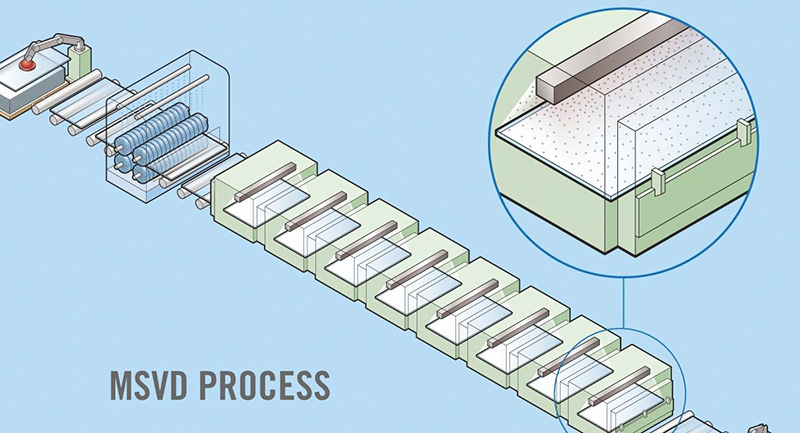

Dukkanin nau'ikan gilashin low-e, masu wucewa da sarrafa hasken rana, ana samar dasu ta hanyar hanyoyin samarwa na farko guda biyu - pyrolytic, ko "hard coat", da Magnetron Sputter Vacuum Deposition (MSVD), ko "laushi mai laushi". A cikin tsarin pyrolytic, wanda ya zama gama-gari a farkon shekarun 1970, ana amfani da murfin a kintinkirin gilashin yayin da ake samar da shi a layin ninkaya. Shafin sa'an nan “fis” zuwa saman gilashin mai zafi, yana ƙirƙirar ƙaƙƙarfan haɗin da yake dawwama sosai don sarrafa gilashin yayin ƙirƙira. A ƙarshe, an yanka gilashin a cikin takaddun hannun jari na masu girma dabam don aikawa ga masu ƙirƙira su. A cikin aikin MSVD, wanda aka gabatar a cikin shekarun 1980 kuma ana ci gaba da yin gyare-gyare a cikin shekarun da suka gabata, ana amfani da murfin ba-layi ba don yanke gilashin da aka riga aka yanke shi a ɗakunan ɗumi a ɗakin zafin jiki.

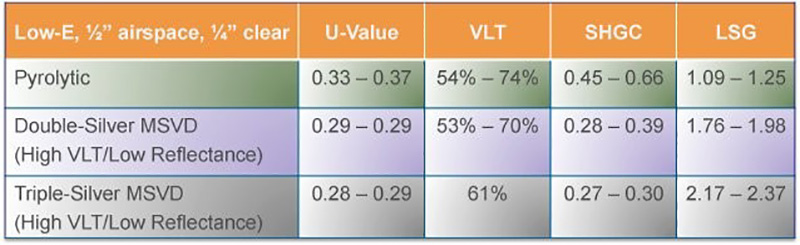

Saboda juyin halittar tarihi na waɗannan fasahohin sutura, wasu ƙananan ƙananan e-hade suna da alaƙa da aikin pyrolytic da sarrafa hasken rana ƙananan-e rufi tare da MSVD, kodayake, wannan ba cikakke cikakke bane. Kari akan haka, aiki ya banbanta sosai daga samfur zuwa samfur da mai sana'anta zuwa mai kerawa (duba tebur da ke ƙasa), amma ana samun samfuran bayanan aikin kuma ana iya amfani da kayan aikin kan layi da yawa don kwatankwacin dukkan kwalliyar-e da ke kasuwa.

Wurin Shafi

A cikin daidaitaccen rukuni na IG akwai wurare huɗu masu yuwuwa waɗanda za a iya amfani da sutura zuwa gare su: farfajiyar farko (# 1) tana fuskantar a waje, na biyu (# 2) da na uku (# 3) suna fuskantar juna a cikin gilashin injin gilashi kuma an raba su ta wani yanki wanda yake haifar da sararin samaniya, yayin da na hudu (# 4) yake fuskantar kai tsaye a cikin gida. Coatananan-e coatings aiki mafi kyau a lokacin da a kan uku ko na huɗu (mafi nisa daga rana), yayin da hasken rana iko low-e coatings aiki mafi kyau a lokacin da a kan Lite mafi kusa da rana, yawanci na biyu surface.

Matakan Ayyukan atingananan-e

Ana amfani da suturar low-e zuwa wurare daban-daban na sassan gilashin rufi. Ko ana ɗaukar ƙaramin e-mai wucewa ko sarrafa rana, suna ba da haɓaka cikin ƙimar aikin. Ana amfani da waɗannan don auna tasirin gilashi tare da ƙananan rufin e:

• U-Darajar shine kimantawar da aka yiwa taga dangane da yawan asarar zafin da take bayarwa.

• Bayyanar da Haske Mai Bayyanuwa ma'auni ne na yadda haske ke wucewa ta taga.

• Gwanin Samun Haske mai amfani da hasken rana shine rabo daga abinda ya faru da hasken rana da aka shigar ta wata taga, duka ana watsa su kai tsaye kuma ana sha dasu & an sake haskaka su a ciki. Ananan ƙarfin haɓakar zafin taga na taga, ƙarancin hasken rana yake watsawa.

• Haske zuwa Samun Rana shine rabo tsakanin taga na Hasken Haske na Hasken rana (SHGC) da ƙimar watsawar hasken haske (VLT).

Anan ga yadda rufin yake aunawa ta hanyar rage adadin ultra-violet da infrared light (makamashi) wanda zai iya wucewa ta gilashi ba tare da lalata girman hasken da ake gani ba wanda ake watsawa.

Lokacin da ake tunanin zayyanar taga: girman, tint da sauran kyawawan halaye suna tuna. Koyaya, rufin ƙananan-e suna taka muhimmiyar rawa kuma suna tasiri sosai game da aikin taga gabaɗaya da yawan dumama, hasken wuta, da farashin sanyaya na gini.

Post lokaci: Aug-13-2020